HULLMOS Sloshing Monitoring provides

valuable data for safe sea transport

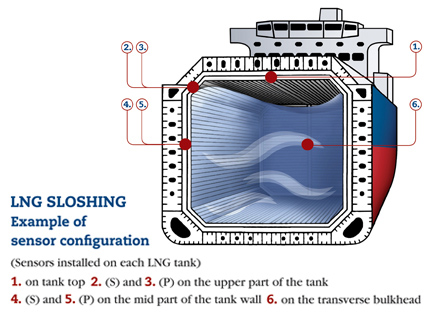

On LNG carriers the membrane and insulation boxes in the tanks need protection against sloshing induced loads. To monitor the loads we have developed a measuring concept, which can be used to put threshold values based on research done by GTT and different classification societies.

The system is implemented in connection with HULLMOSŪ Hull Monitoring System. The integrated systems provide prediction, warning, measurement and assistance to the crew in real time and additionally the system collects valuable data for evaluation afterwards.

Due to increased size and loading capacity of LNG carriers, reliable measurement of sloshing induced loads on tank structures is needed. Sloshing and sloshing impact loads cannot be accurately estimated with computational models or calculations due to unpredictable motions of the fluid in tank. Therefore reliable prediction of impact pressures is not possible without measuring the phenomenon in real time.